3D printing has a real advantage in the industry. No more constraints, the printer perfectly realizes a model created on computer. The interest of this solution is twofold, its cost and its reliability. Not only does this solution save you time and money, but the possibilities of creation are infinite!

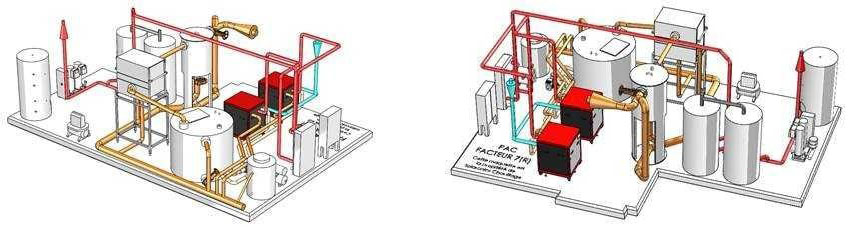

Our customer trusted us to develop its 3D model. This model was realized within the framework of a training of the collaborators to better visualize the system of boiler room of the company.

Discover the steps of his project, from modeling to manufacturing.

Step 1: Evaluation of the project by our design office

To ensure the conformity of the model and guarantee its feasibility, our client was followed by a business manager who accompanied him in his project from the beginning.

A specification was established to specify the layout of the elements, the possibility or not to dismantle them and the color codes to be used.

Step 2: Making the model

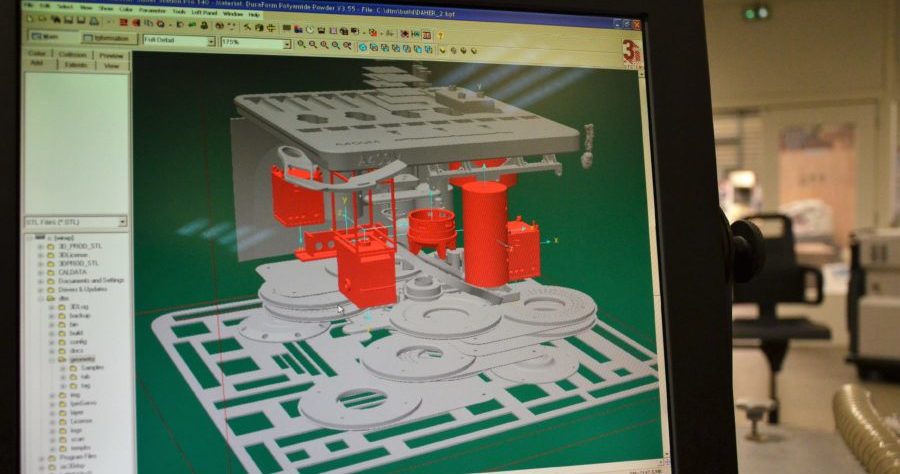

Once the model is validated by our design office, it goes into production!

Here we have chosen the laser sintering in powder to manufacture the parts! Laser sintering brings an important resistance ensuring a good ageing of the model during the various manipulations. Moreover, laser sintering makes it possible to produce very complex parts, and is perfectly suited to functional tests.

Step 3: De-welding the parts

After the production and cooling, the parts rest on a bed of unprocessed powder. The printing is carried out by theagglomeration of the particles of material thanks to a CO2 laser beam. Laser fusion.

Carefully we strip and sandblast the thermoplastic parts.

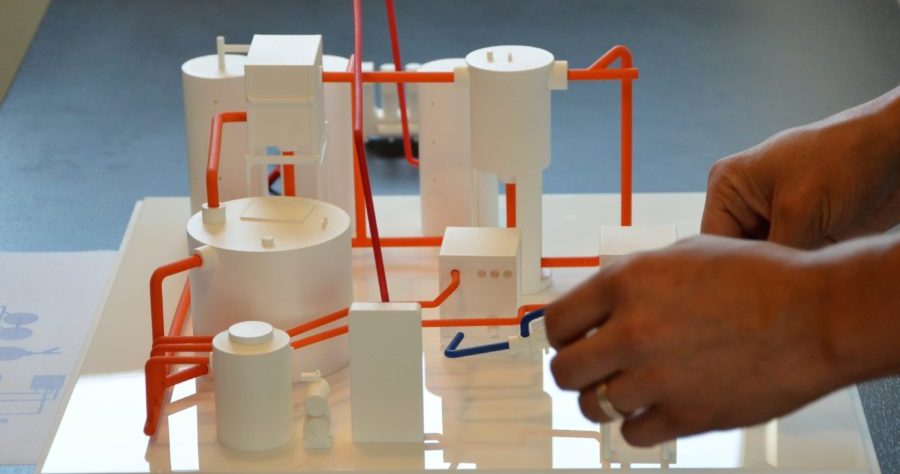

Step 4: Painting and assembly

Each element is carefully painted for an impeccable finish.

The different parts of the model are then assembled and fixed on the base.

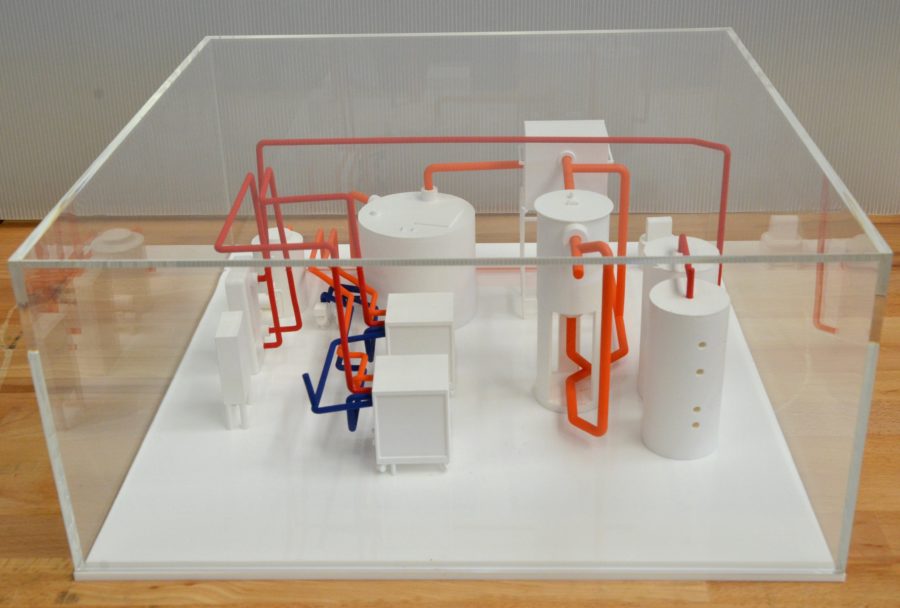

Step 5: Finalized model

The model is finally protected by a removable plexiglass cover. For this type of application where there will be a lot of handling, laser sintering is well adapted because it guarantees a good robustness of the whole.

As you can see on this 3D model of a boiler room system, laser sintering allows the realization of a very complex functional model.

Learn more about 3D printing by laser sintering ?