The advantages of wire deposition

Good mechanical resistance

Price

Respect of geometries

A thermoplastic

thermoplastic material

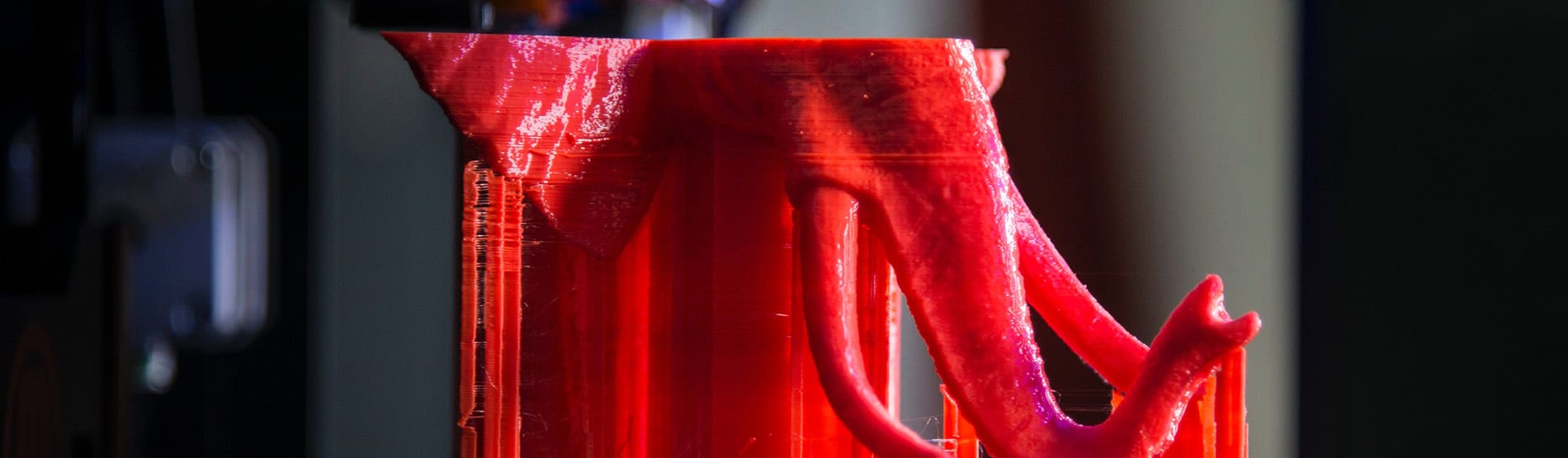

Wire deposition is a technology that allows to manufacture parts by adding material. The materials used are thermoplastic polymers.

Manufacturing

by extrusion

The machine works a bit like an extruder, bringing the material to its melting point to create a wire of about 0.05 millimeters in diameter. The nozzle moving on the x, y axes allows to deposit this hot wire on a layer. The platform descends between each sequence to stack the layers on top of each other.

Functional parts

and mock-ups

Fused deposition is used in many fields: automotive, aerospace, architecture, medical, art...

Due to its properties, it can be used to print functional parts, models and prototypes.

Available materials

The material available for wire deposition.

Contact us today!

Our team will get back to you to discuss your specific needs, so that we can help you achieve your goals.