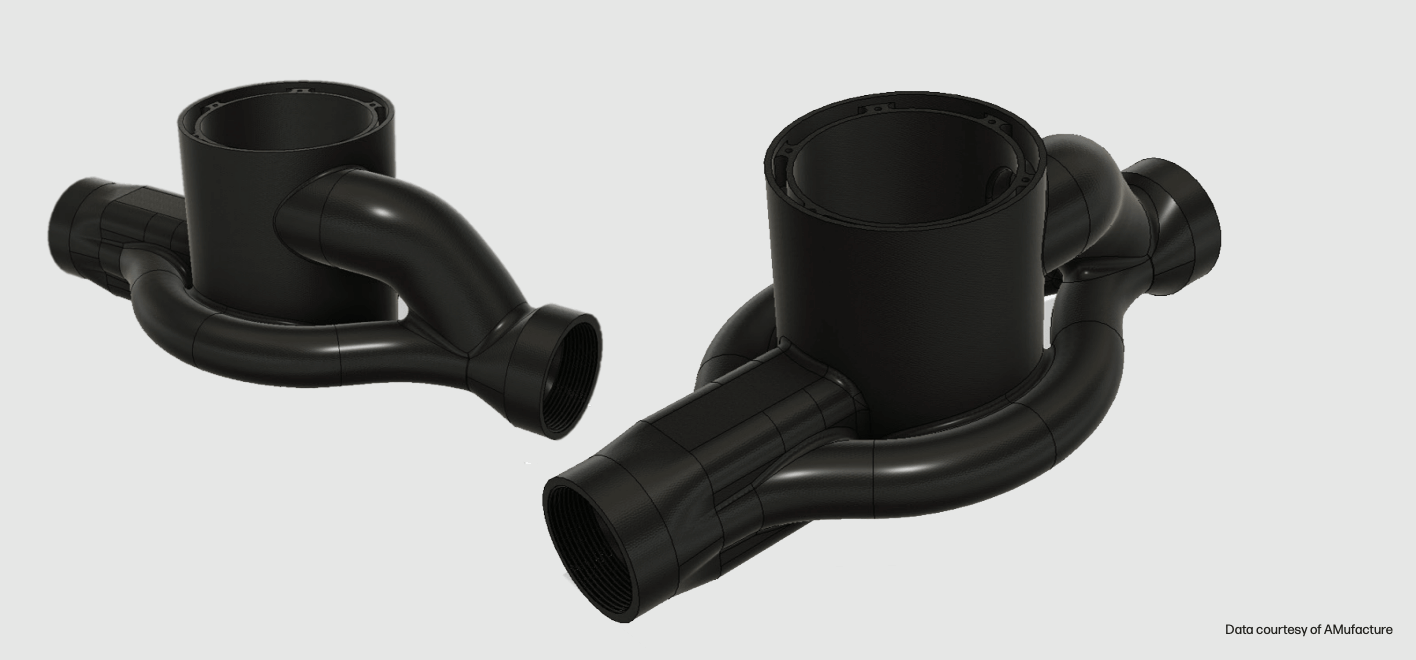

Case study: Multi Jet Fusion technology for a complex, lightweight, watertight manifold for racing yachts

In the demanding field of yacht racing, lightness, precision and reliability of components are essential criteria. British additive manufacturing specialist AMufacture has risen to the challenge, designing and producing a bespoke hydraulic manifold for a 52-foot yacht destined for a transatlantic crossing.

Context: optimizing a critical component under severe constraints

The specifications called for one room:

-

Ultra-light to fit into the carbon structure of the sailboat,

-

Waterproof and functional at 20 bar continuous pressure,

-

Produced in less than 10 days.

Faced with these constraints, traditional manufacturing methods proved unsuitable, in terms of lead times, mechanical performance and geometric freedom.

Technological solution: Multi Jet Fusion 5210 and PA12 material

AMufacture mobilized its Jet Fusion 5210 printer to produce the manifold in PA 12 HR (High Reusability). This technical material offers excellent resistance to pressure and water, while guaranteeing a homogeneous finish after chemical smoothing and black tinting.

Thanks to Multi Jet Fusion technology, the part could be printed with :

-

Complex internal chambers,

-

A perfectly hydrophobic surface,

-

Structural integrity that meets safety and performance requirements.

Results

-

Optimized weight: compatible with carbon construction standards,

-

Watertightness guaranteed: thanks to the intrinsic properties of PA12 and post-treatment,

-

Lead times divided by 4: the part was delivered in 6 days, compared with 4 weeks for traditional production,

-

Validated functional performance: resistance to 20 bar without deformation or leakage.

"This project perfectly illustrates the benefits of additive manufacturing in highly constrained sectors such as competitive boating. At 3DPROD, we are able to produce state-of-the-art, functional, complex and critical naval parts in MJF PA12, in very short lead times, without compromising on performance."

Do you have a manufacturing project? Contact our teams today to receive tailor-made support and benefit from the advantages of additive manufacturing!