All materials are suitable for a wide range of applications such as the production of functional prototypes, test parts, final parts, but their use is mainly dedicated to ultra-precision mass production.

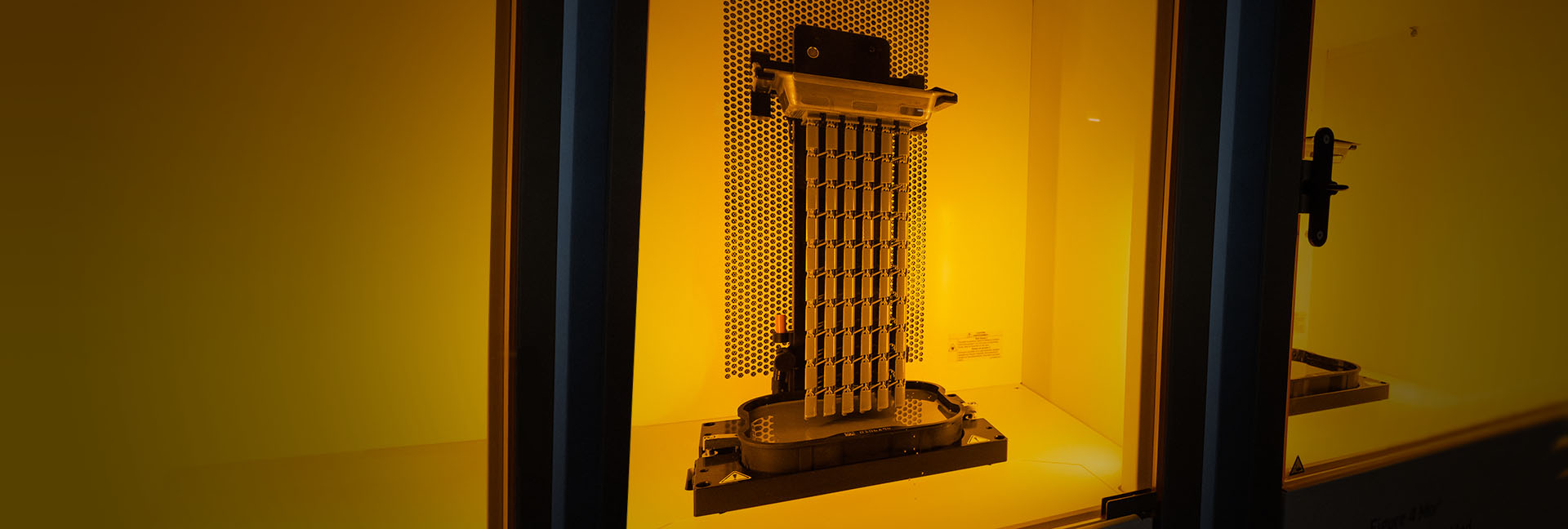

Figure 4® PRO-BLK-10

Rigid materials for the production of durable parts similar in appearance and texture to injection molded parts, with high impact, moisture resistance and long-term environmental stability characteristics.

Properties

- High printing speed (up to 62 mm/h) ;

- Bending temperature under load > 70°C ;

- 12% elongation at break;

- Long-term environmental stability, impact resistance (durability and strength).

Applications

Direct production of black plastic parts; engine housings (crankcases), connectors, snaps, automotive interiors and/or other general purpose parts.

Figure 4® RIGID GRAY

Rigid materials for the production of high contrast serial parts with high impact, moisture resistance and long term environmental stability characteristics.

Properties

- High printing speed up to 48 mm/hr;

- Durable environmental stability of mechanical properties and color in indoor and outdoor applications (tested to 8 and 1.5 years respectively by ASTM methods);

- Deflection temperature under load of 72°C at 0.455 MPa;

- Elongation at break 30 % ;

- Flexural modulus 2,200 MPa.

Applications

Rigid static production components such as housings and covers; Small, precise and detailed parts for consumer and general purpose products; Parts where visualization of detail is essential! (e.g., lettering, markings, textures, surface patterns, etc.)

Figure 4® RUBBER-65A-BLK

Semi-hard elastomeric materials for the production of functional parts with good shape retention and high tear resistance. Ideal for compression applications due to the malleability of the material.

Properties

- Shore-A of 65 (semi-hard rubber);

- Tear strength of 8.5 kN/m, Type-C vertical print on Z axis;

- High elongation at break (125% on XZ axis).

Applications

Production of semi-hard elastomeric parts; housings, vibration dampers, pipe spacers, impact resistance parts, handles.

Figure 4® HI TEMP 300-AMB

High-temperature materials for the production of parts with a deflection temperature under load of up to more than 300°C. High heat resistance providing high stiffness and exceptional stability under extreme conditions.

Properties

- Deflection temperature under load > 300 °C at 0.455 and 1.82 MPa;

- Fire retardant UL 94 VO and FAR 25;

- High tensile modulus (4000 MPa);

- Notched bar impact resistance of 10 J/m ;

- Rigid and translucent.

No secondary heat treatment required

Applications

Rigid plastic for very high temperature environments; HVAC, appliances, motor housings and other test or end use components requiring high heat resistance.

Figure 4® HI TEMP 150-AMB

High-temperature materials for the production of parts with bending temperatures under load of up to 150°C. High heat resistance for outstanding rigidity and stability under extreme conditions.

Applications

Rigid plastic for very high-temperature environments; HVAC, household appliances, motor housings and other test or end-use components requiring high heat resistance.

Request a sample

Our team will get back to you to discuss your specific needs, so that we can help you achieve your goals.