The advantages of selective laser sintering

Resistance

Small series

Supports

A thermoplastic material

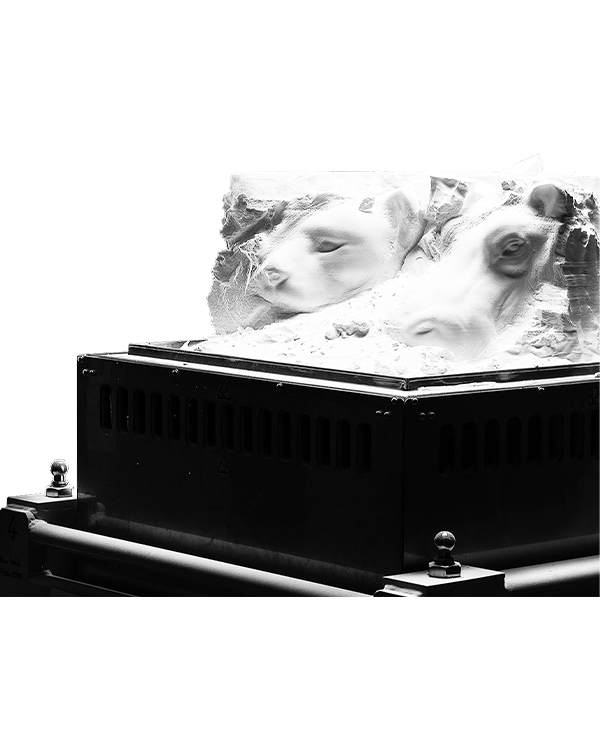

Powder laser sintering (SLS) is a 3D printing technology that consists of manufacturing parts by agglomerating particles of material. The materials used are generally thermoplastics or metals in the form of 50 micron powder.

The powder is agglomerated by successive stacking of layers of about 0.1 mm thick. On each layer, the material is transformed by a laser beam which brings the necessary energy to reach the fusion point.

Technical parts

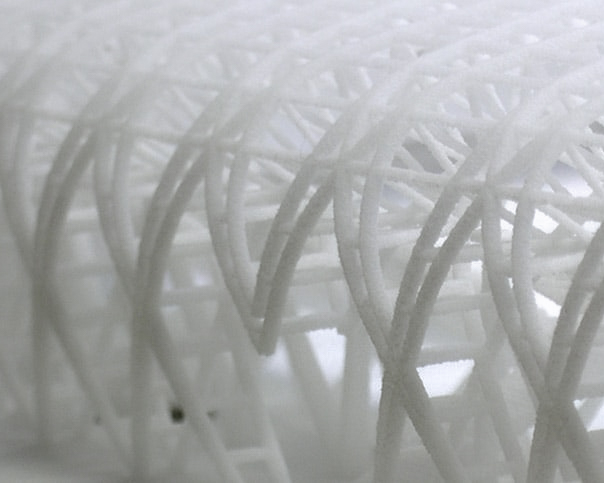

without support

Laser sintering allows to obtain technical materials able to resist mechanical and thermal constraints.

In addition, you will be able to print very complex shapes since no support is used during the manufacturing process, the manufactured parts resting on the unprocessed powder bed.

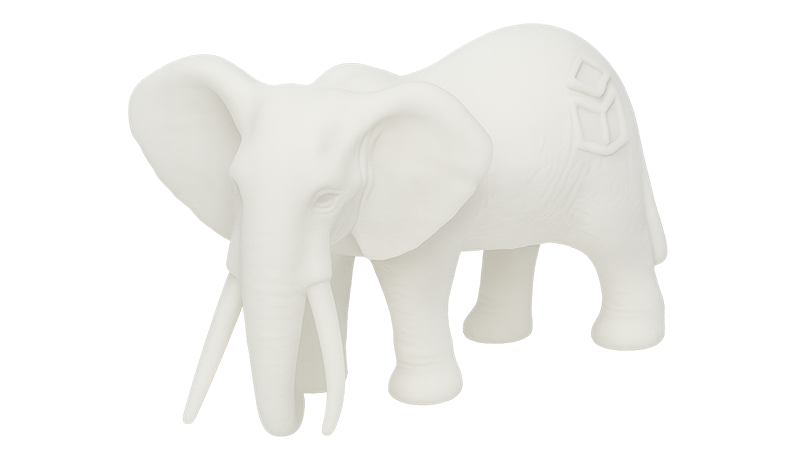

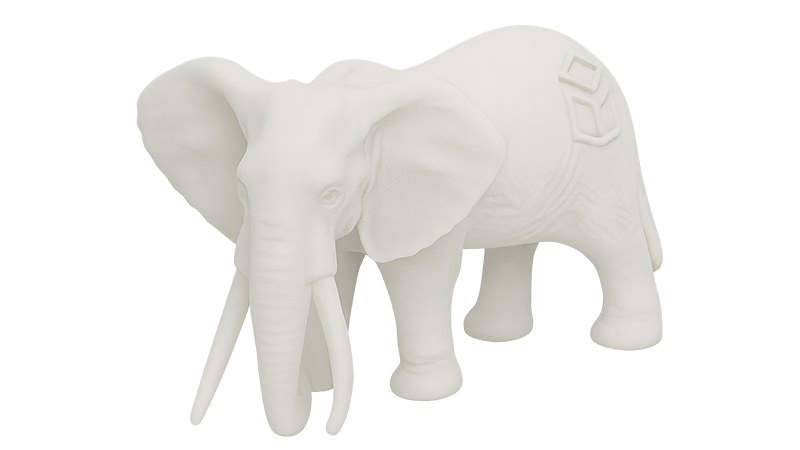

Prototype, tooling, small series in laser sintering

Given its characteristics, powder sintering is particularly used to manufacture functional prototypes, models, tools, and even serial parts.

The materials available for powder sintering are: PA, PAGF and flame retardant PA powder

Our powders for laser sintering

Materials available for laser sintering

The materials available for powder sintering are: PA, PAGF and flame retardant PA powder.

Contact us today!

Our team will get back to you to discuss your specific needs, so that we can help you achieve your goals.