The advantages of 3D SLS printing with 3DPROD

Resistance

Small series

Reactivity

What is Laser Sintering SLS?

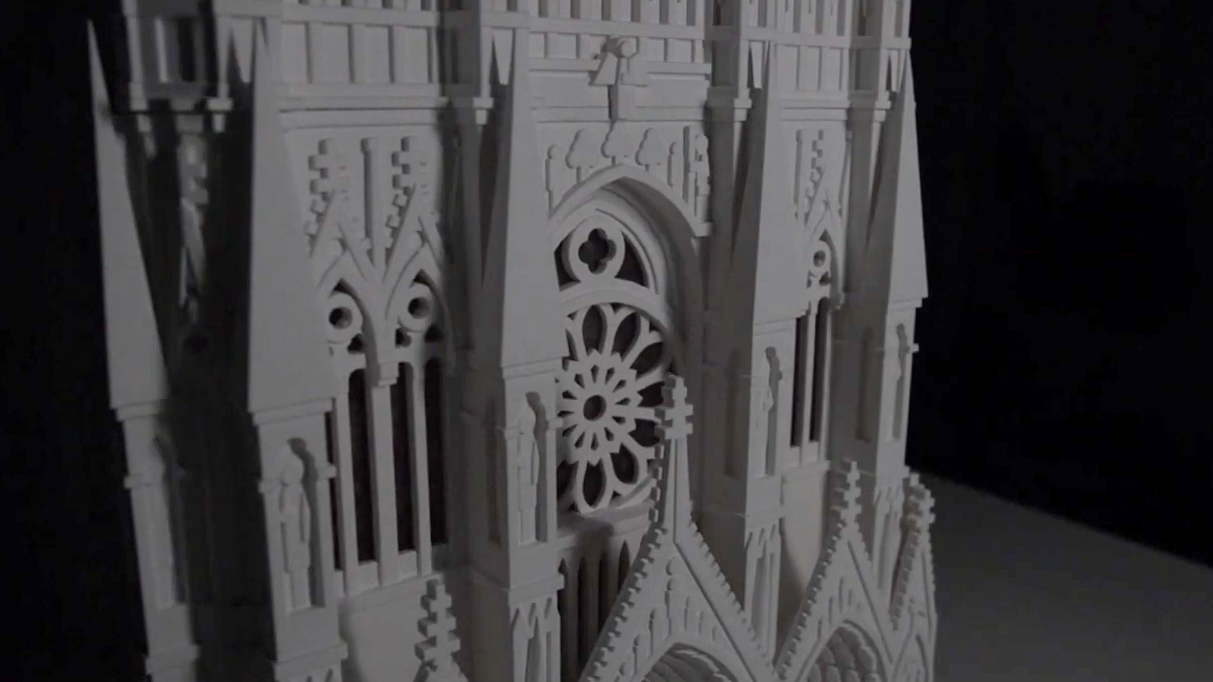

Powder laser sintering (SLS) is a 3D printing technology that consists of manufacturing parts by agglomerating particles of material. The materials used are generally thermoplastics or metals in the form of 50 micron powder.

The powder is agglomerated by successive stacking of layers of about 0.1 mm thick. On each layer, the material is transformed by a laser beam which brings the necessary energy to reach the fusion point.

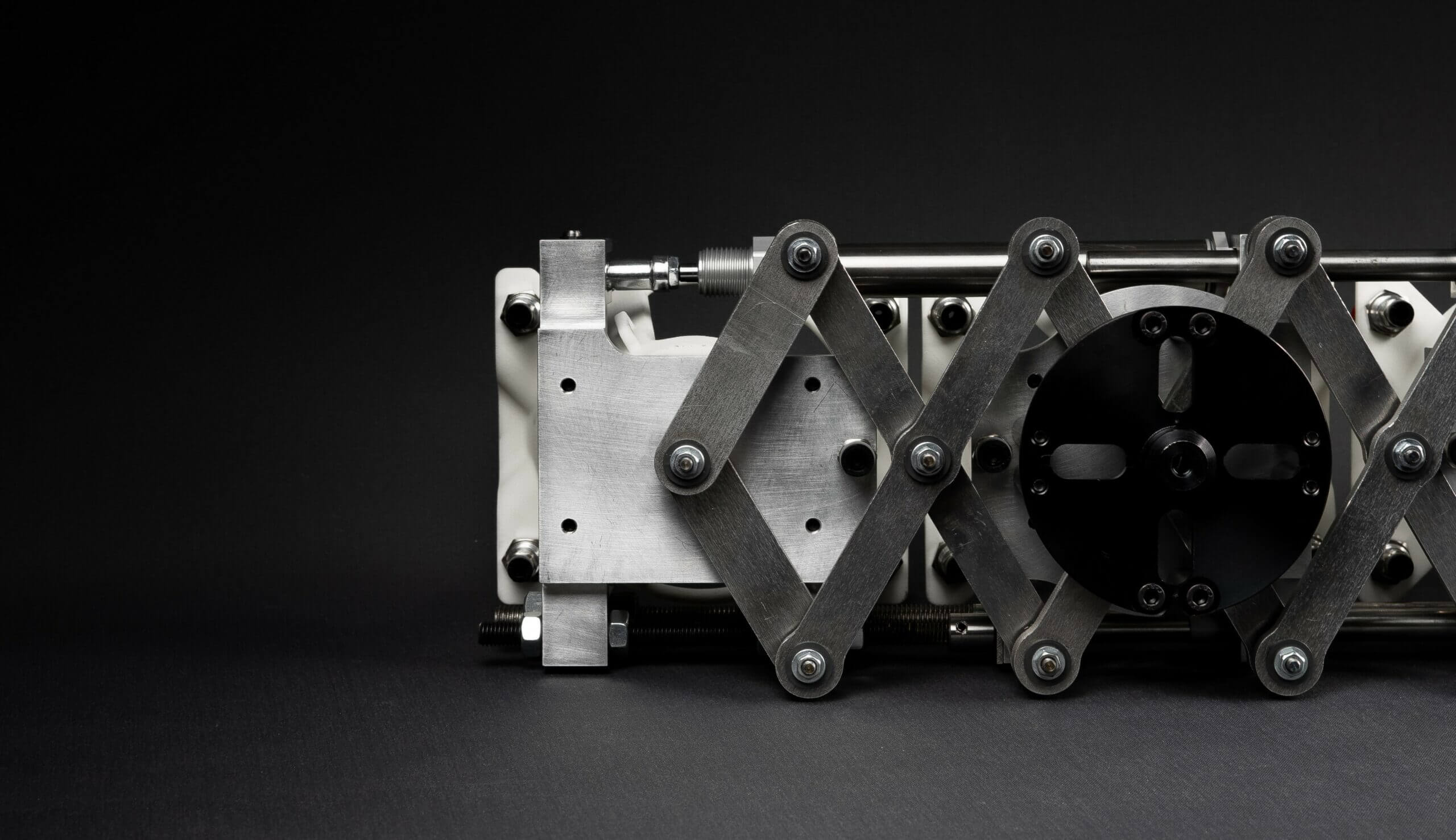

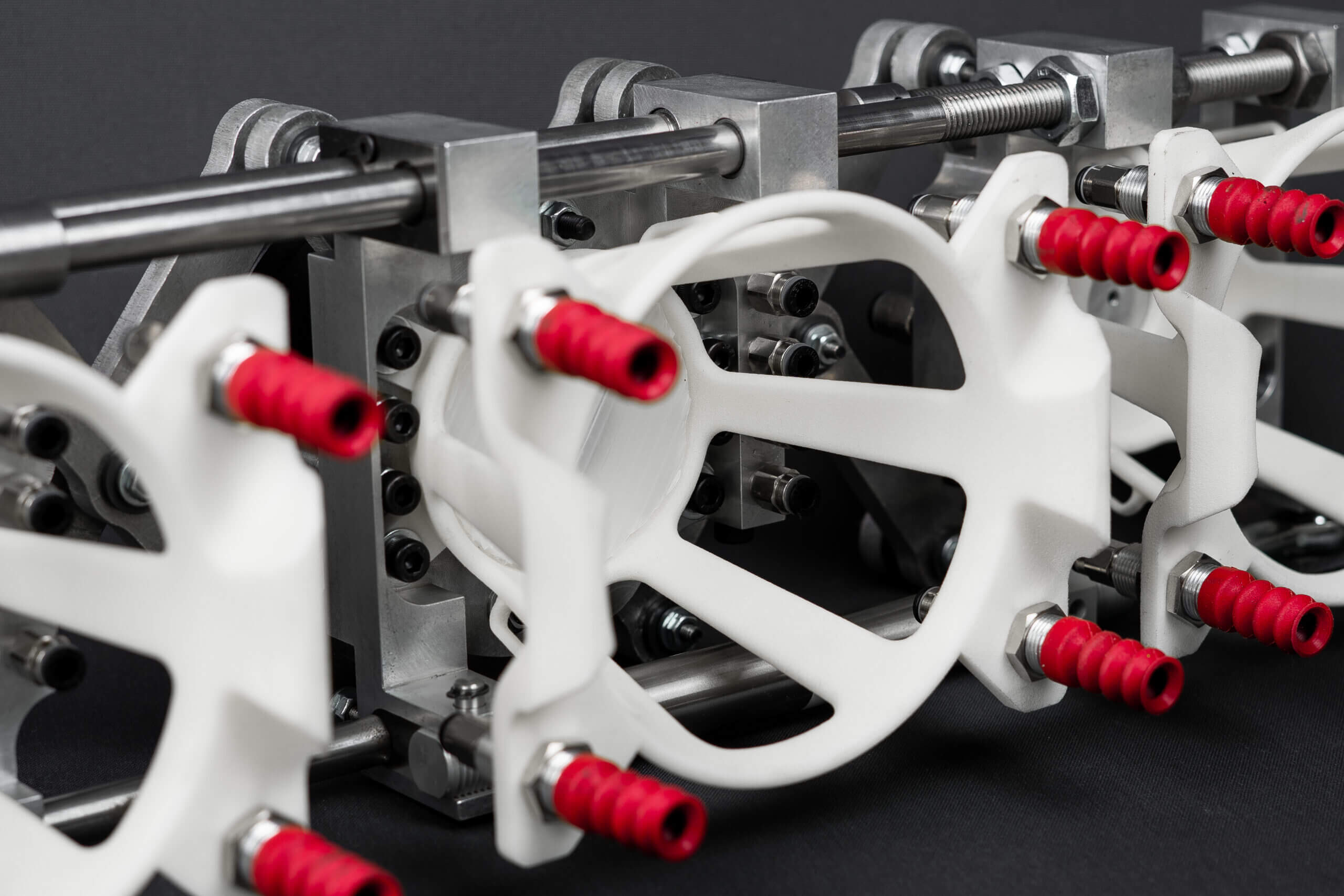

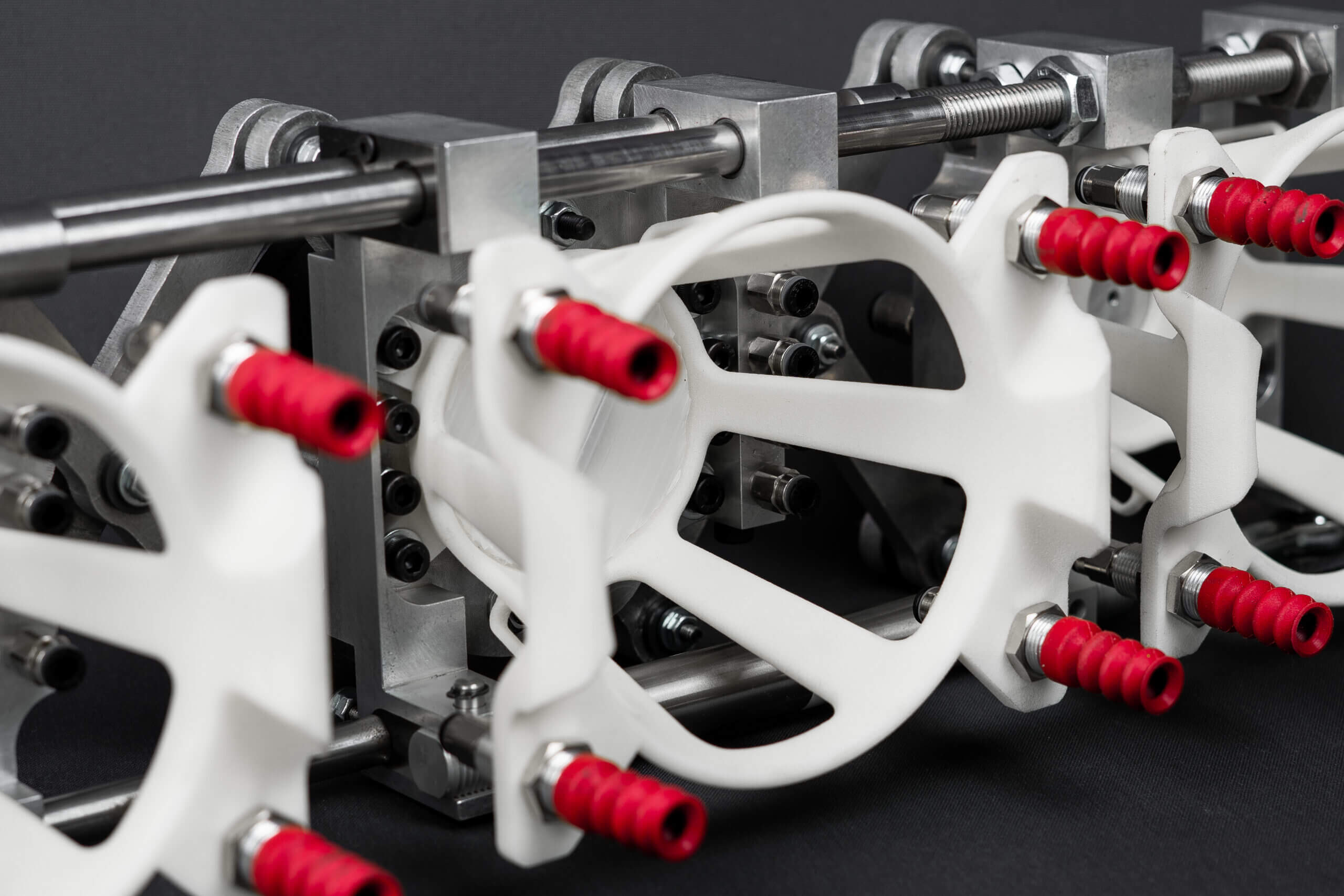

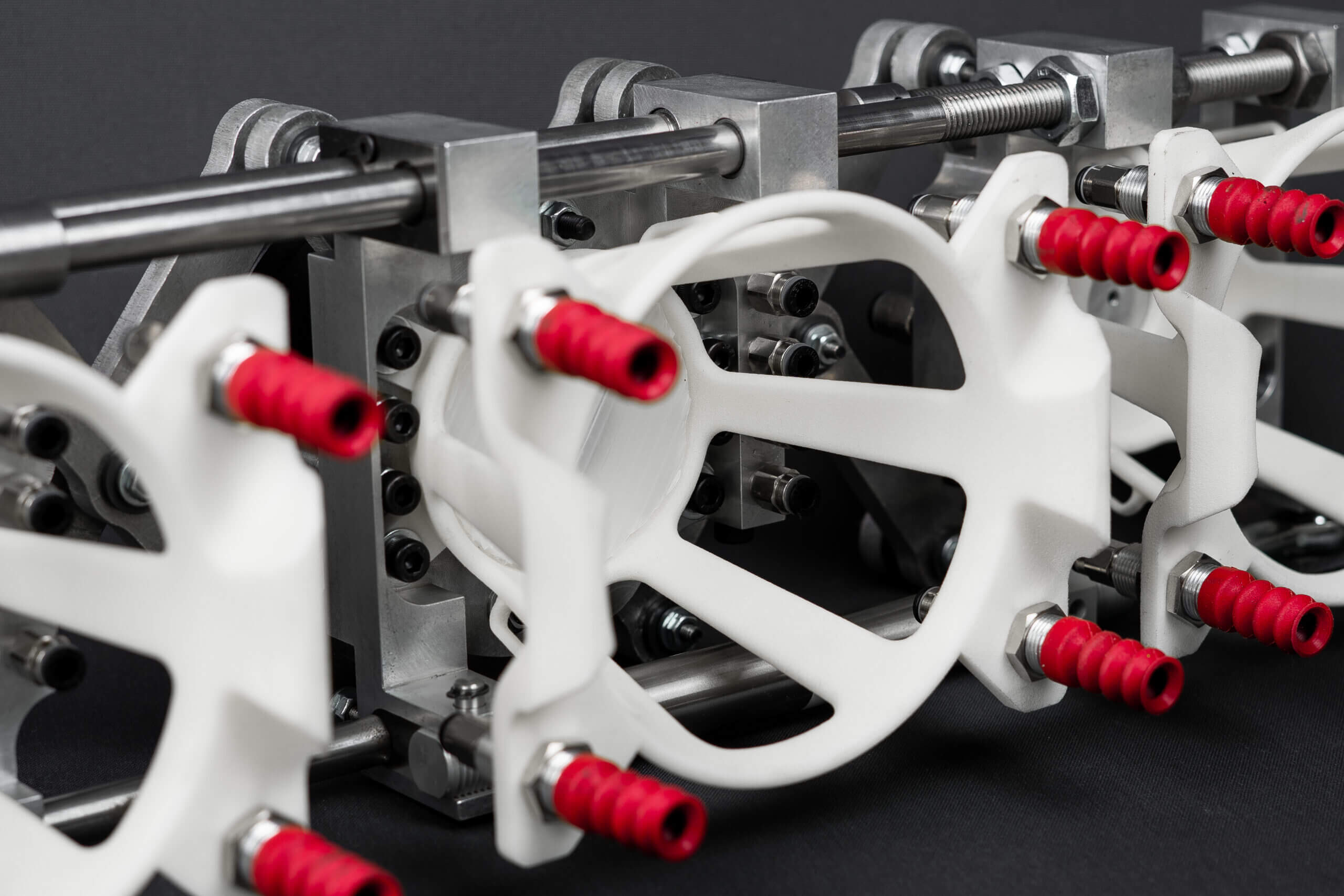

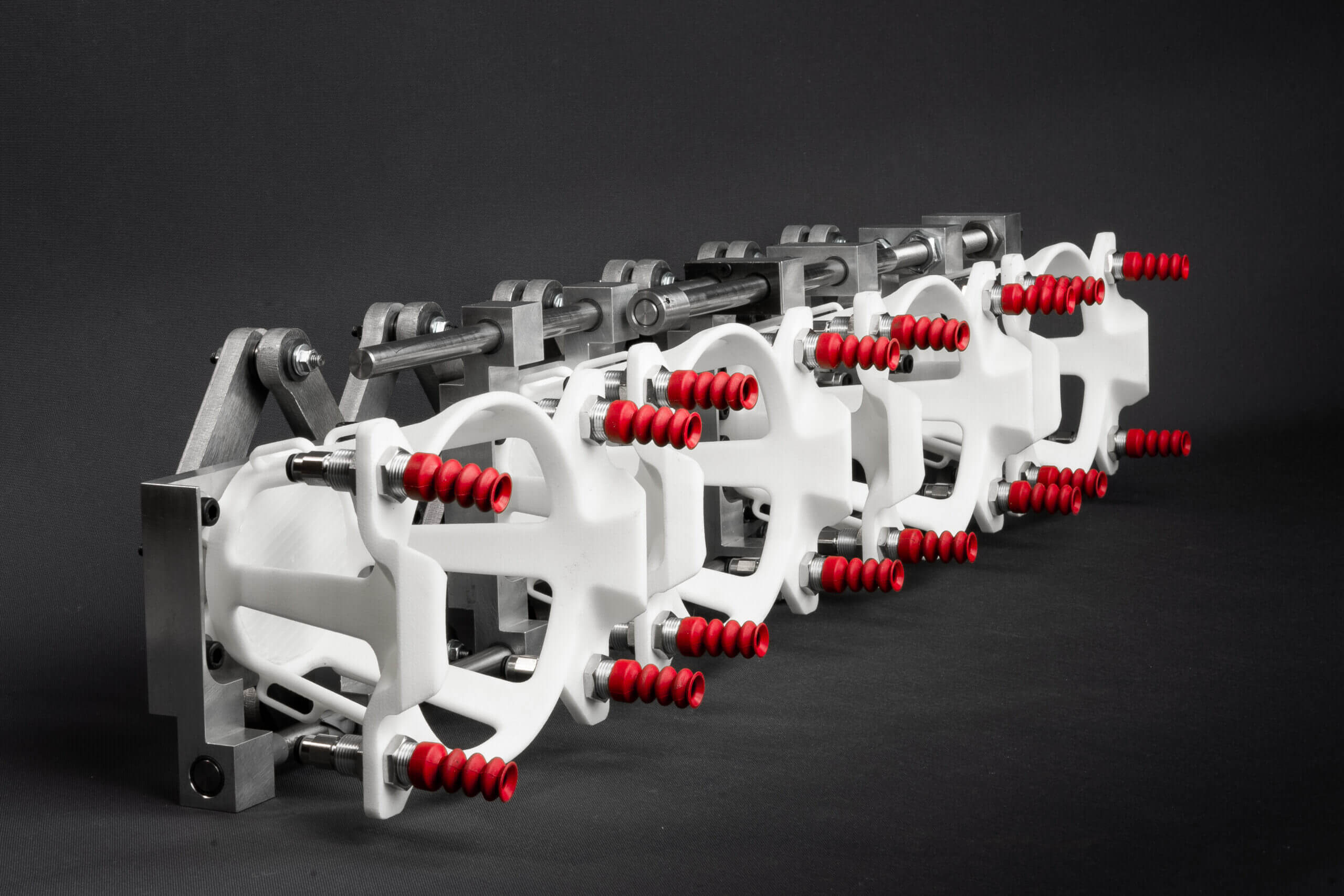

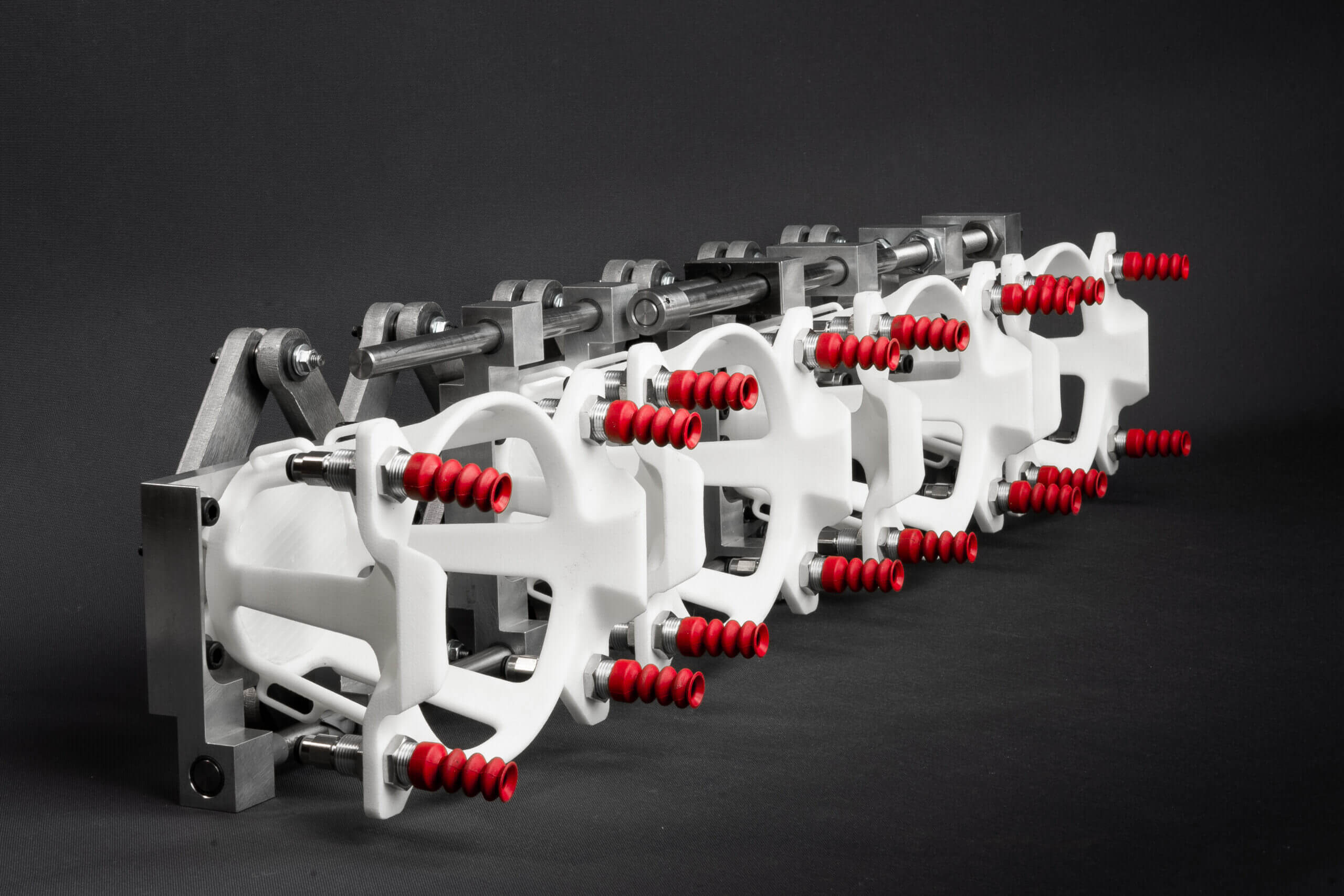

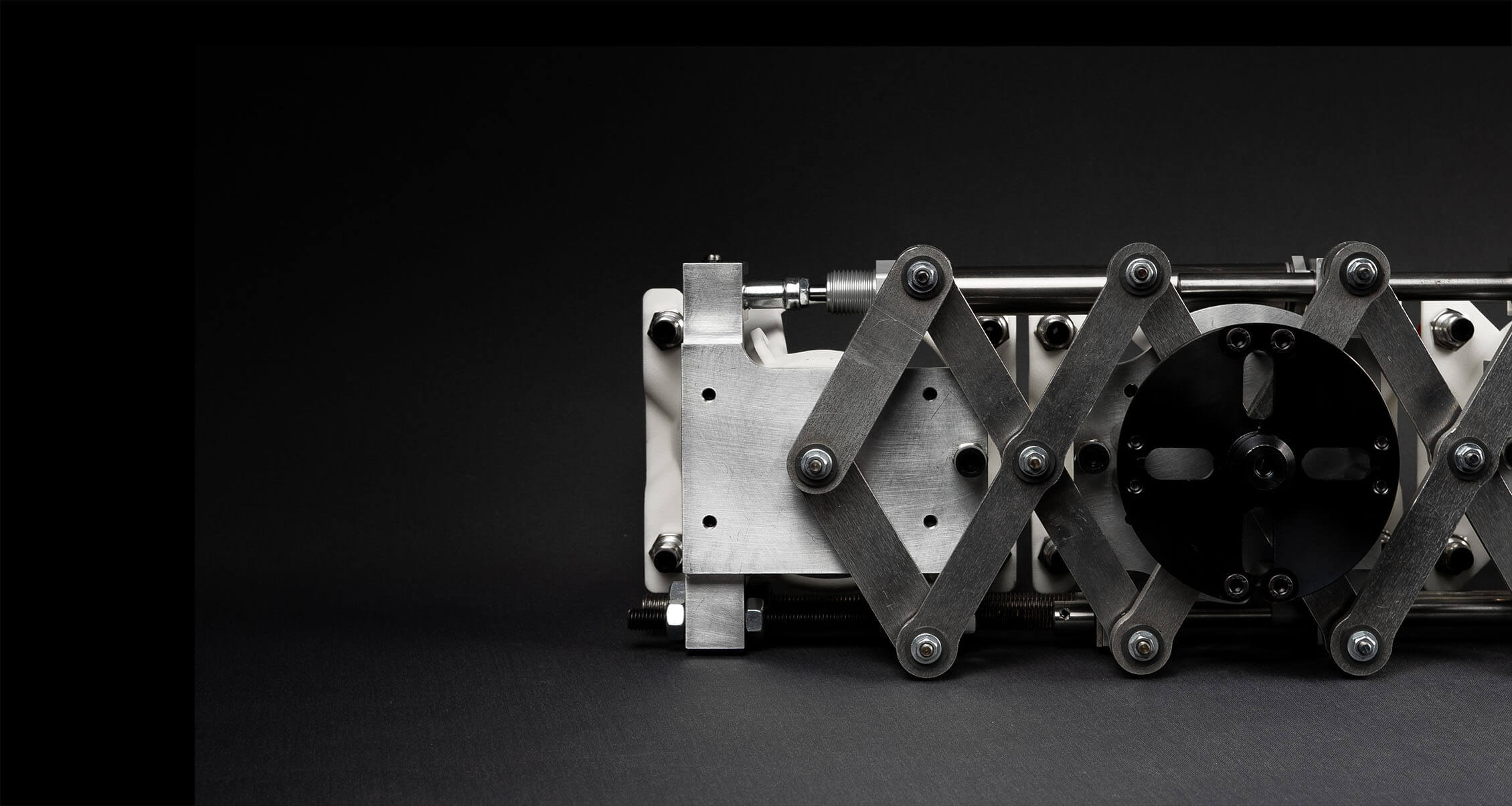

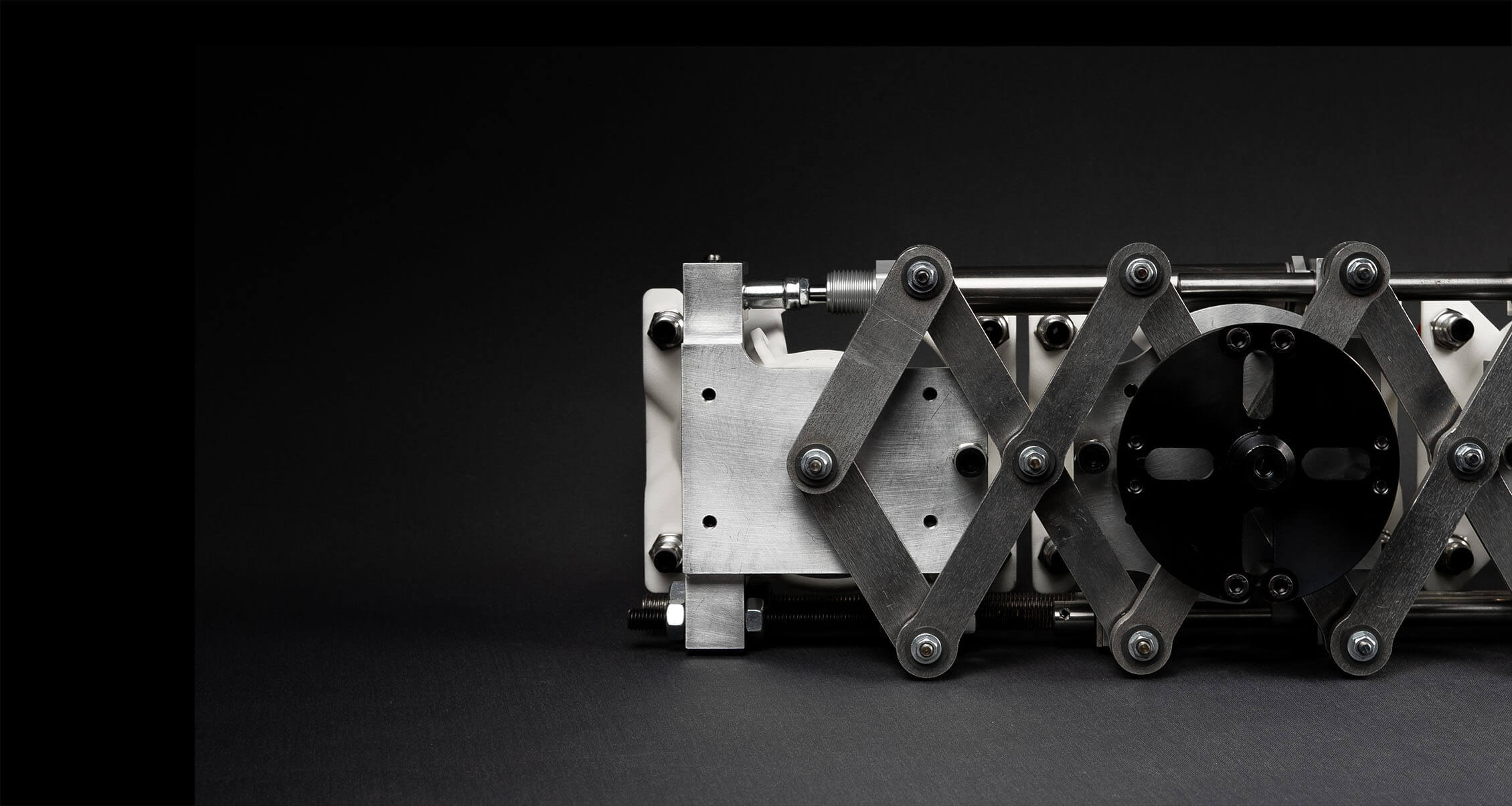

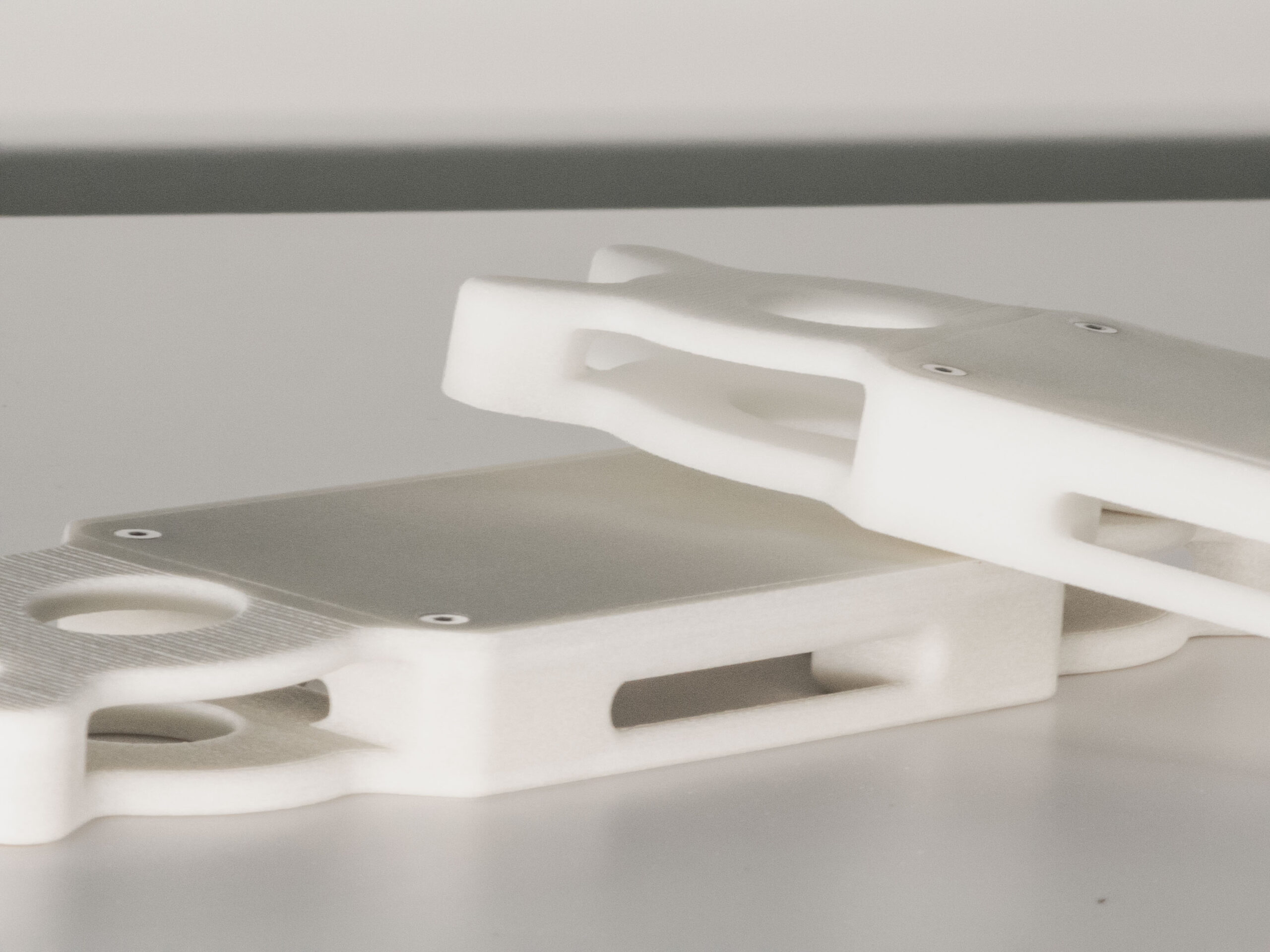

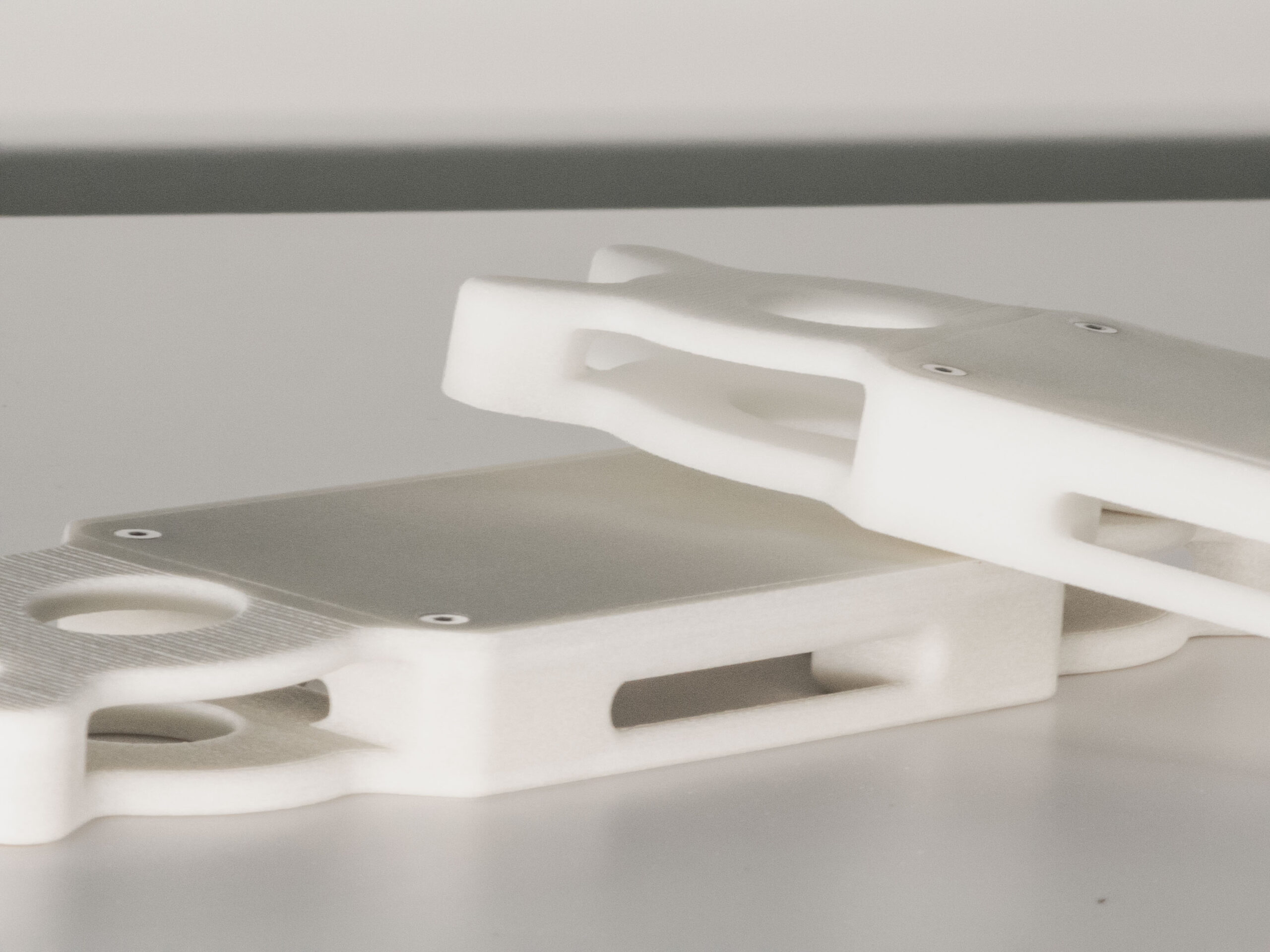

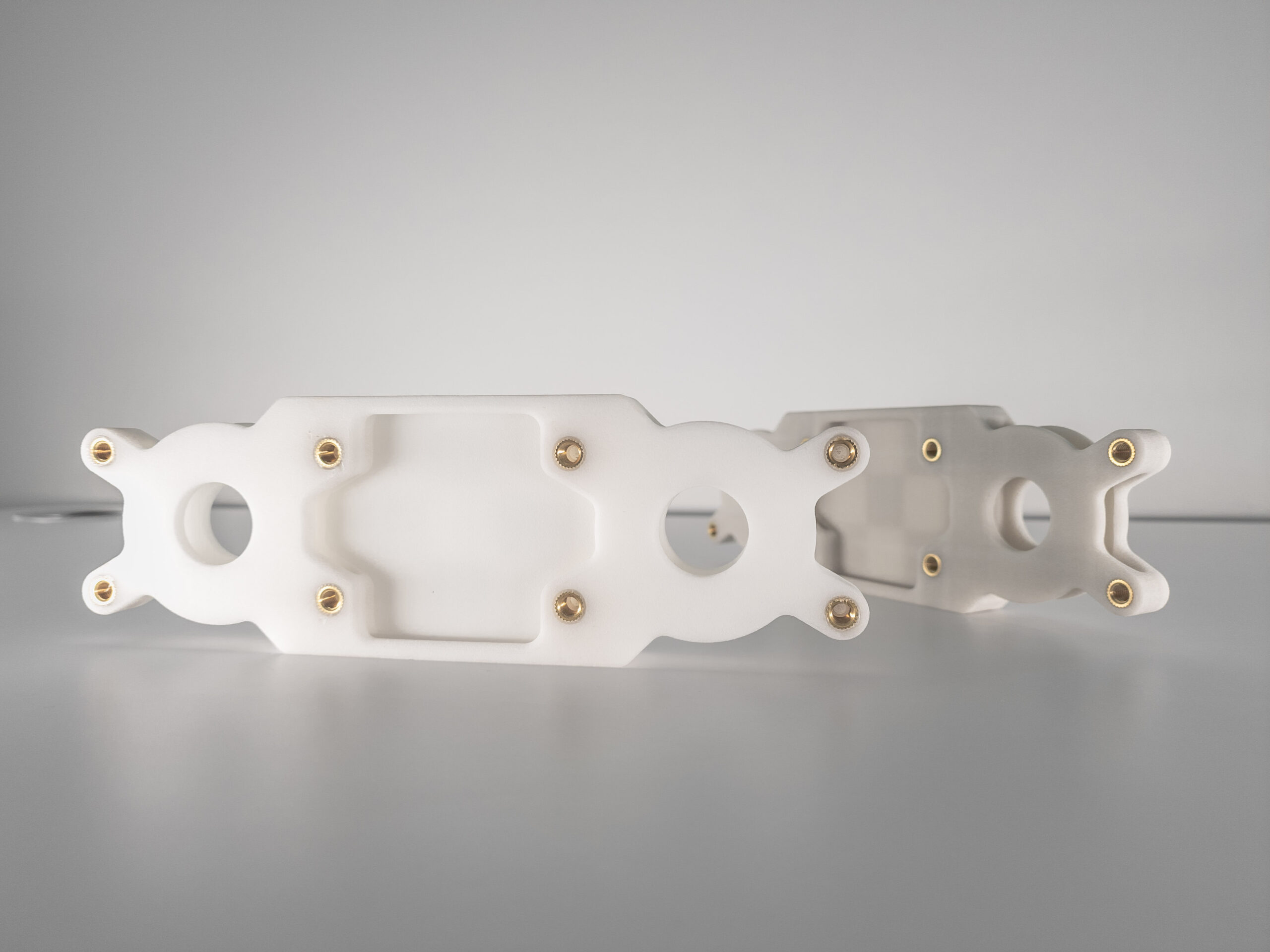

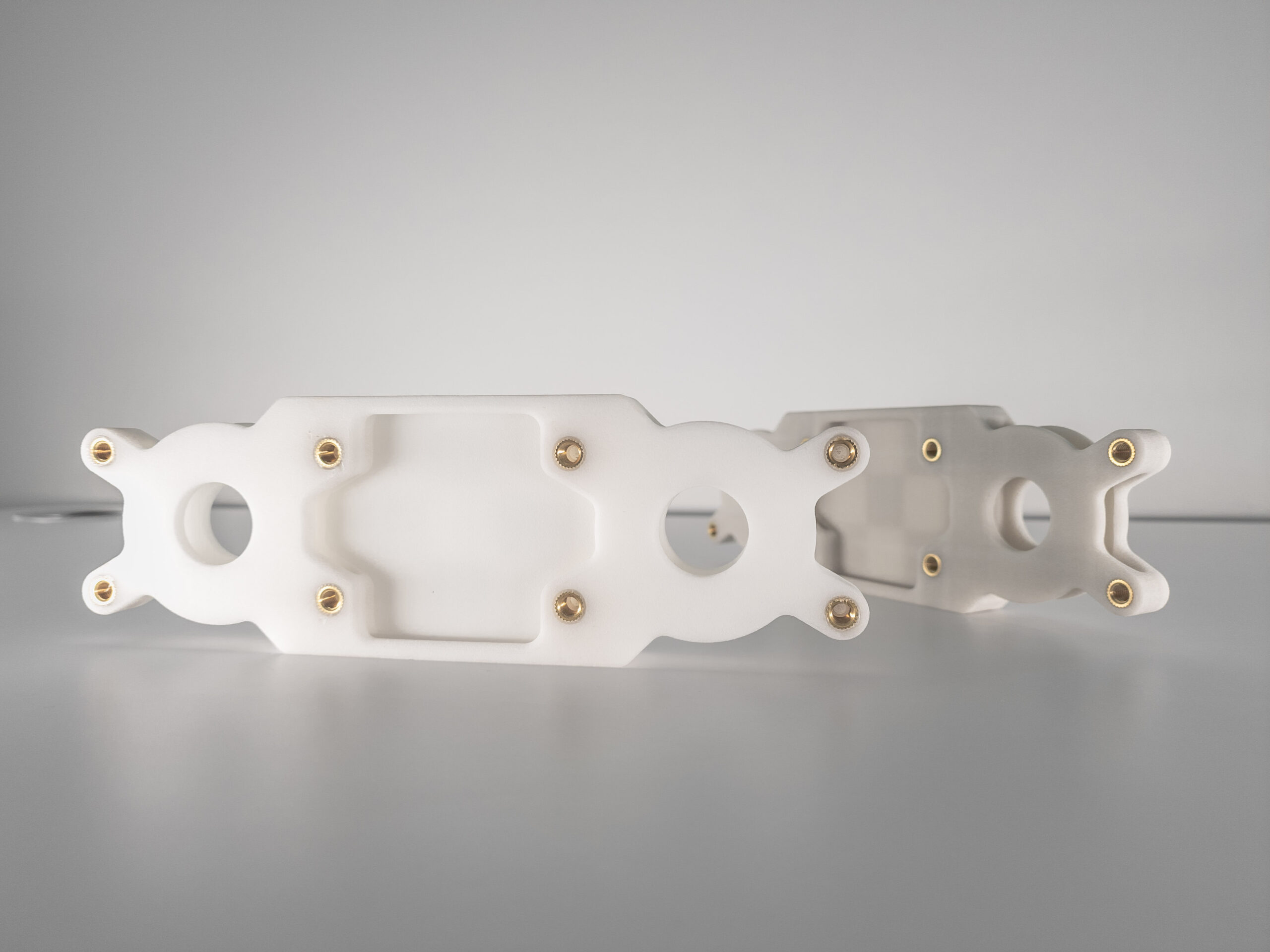

Prototype, tooling, small series in Laser Sintering

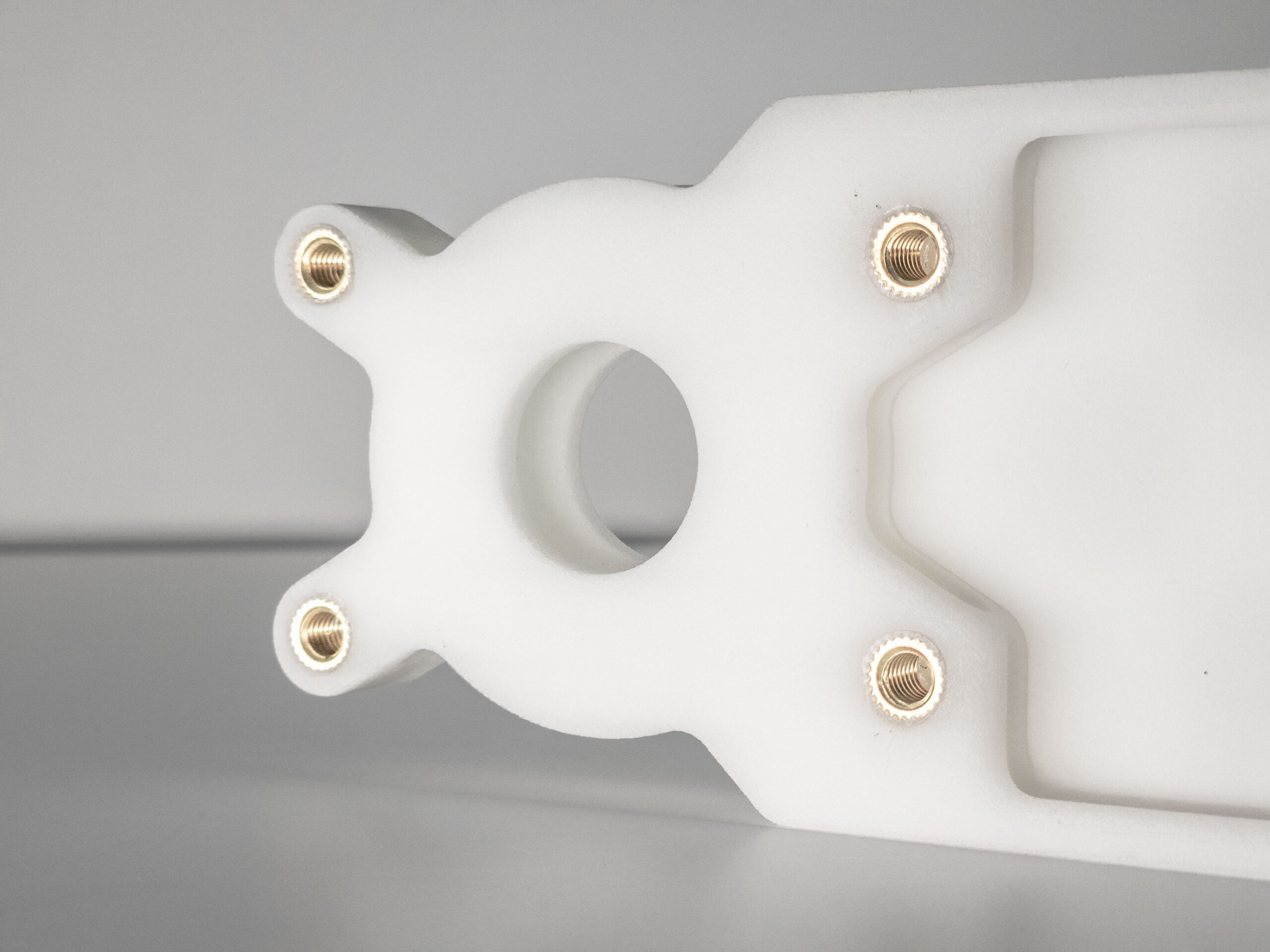

Laser sintering produces technical materials capable of withstanding mechanical and thermal stresses. Given its characteristics, powder sintering is particularly well-suited to the manufacture of functional prototypes, mock-ups, tooling and even mass-produced parts.

The materials available for powder sintering are: PA, PAGF and flame-retardant PA powder.

The powder is agglomerated by successive stacking of layers of about 0.1 mm thick. On each layer, the material is transformed by a laser beam which brings the necessary energy to reach the fusion point.

PA powder (SLS)

PAGF powder (SLS)

Flame retardant PA powder (SLS)

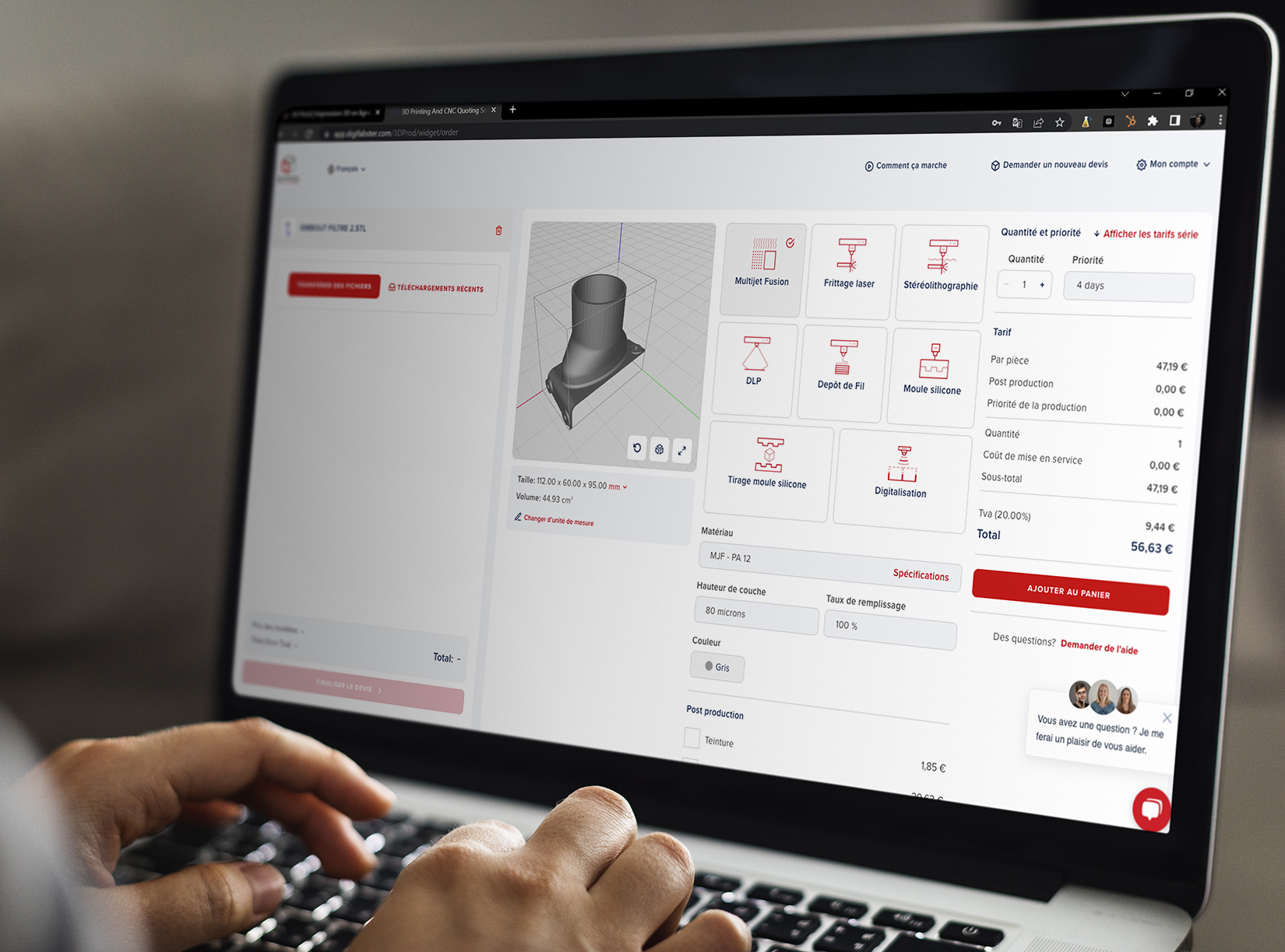

Your quote in minutes

Choose the technology, the material, the finish and get your quote instantly via our online platform.

1. Import your CAD file

Upload your 3D file (.stl, .obj, .wrl, .step (.stp), .iges (.igs), .3mf, .dxf or .zip (with models and textures) file not exceeding 100 Mb

2. Choose 3D technology and materials

Choose the ideal material from our range of laser sintering powders and finishes and order online.

Our experts are at your disposal for all your 3D projects

FAQ about SLS Laser Powder Sintering

Contact us today to discuss your project!

Our team will get back to you to make your project a reality!