The advantages of vacuum casting with 3DPROD

Various resins

Accuracy

Mechanical resistance

What is Vacuum Casting ?

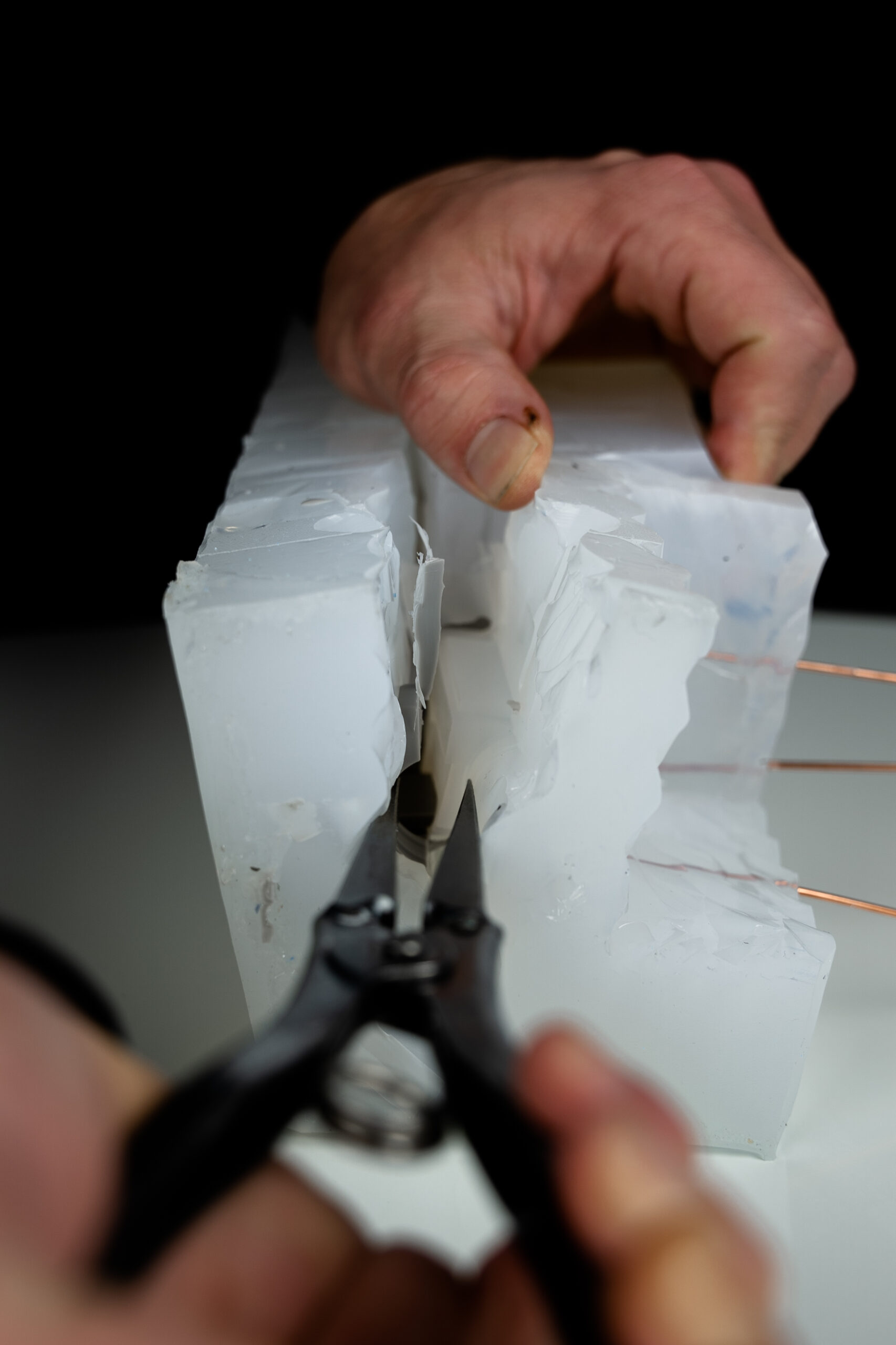

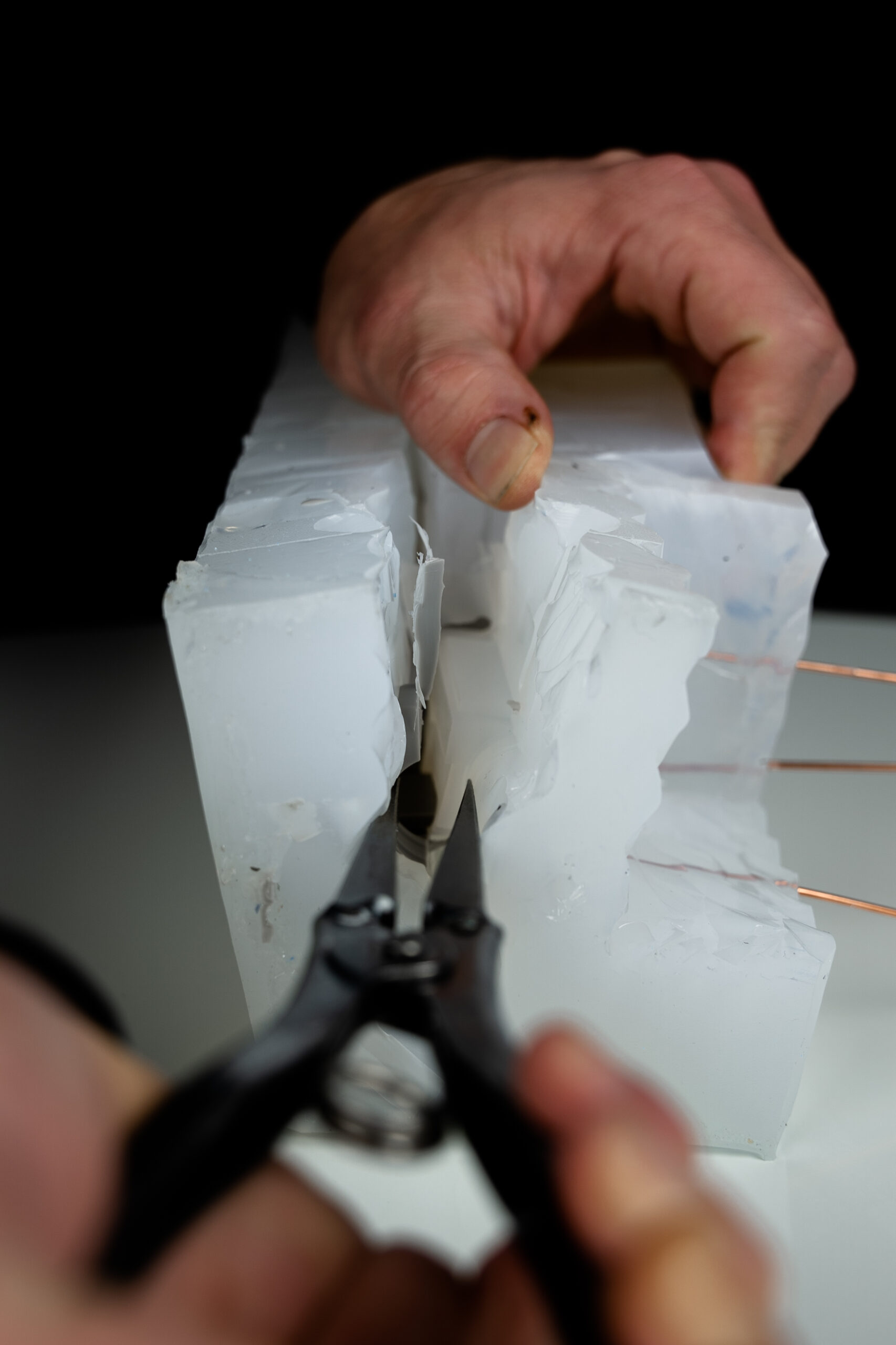

The vacuum casting technique is an unrivalled method of faithfully reproducing a part, taking advantage of a silicone mold created from a model usually produced using Stereolithography. Once the mold has been made, a polyurethane resin is poured in, naturally adopting the shape of the impression.

This approach offers remarkable diversity in terms of materials, hardness levels and colors. As a result, prototypes can be produced that perfectly match the original model, guaranteeing exceptional quality. Vacuum casting is emerging as a cost-effective solution, particularly suited to the production of small series, prototypes and pre-series without the need for plastic injection.

The advantages of Vacuum Casting

Vacuum casting is used to produce parts in small and medium series (up to a maximum of 25 runs per mold) with high precision of detail and surface finish.

This technology can be a more economical alternative to plastics processing for the production of small industrial runs, as it requires less investment in equipment and tooling (plastics processing requires specific molds, which take a long time to make). What's more, vacuum casting offers the possibility of modifying colors and materials during different runs (useful for A/B testing).

Don't hesitate to contact our experts: we can help you to bridge the gap between injection molding and 3D printing.

Wide choice of resins

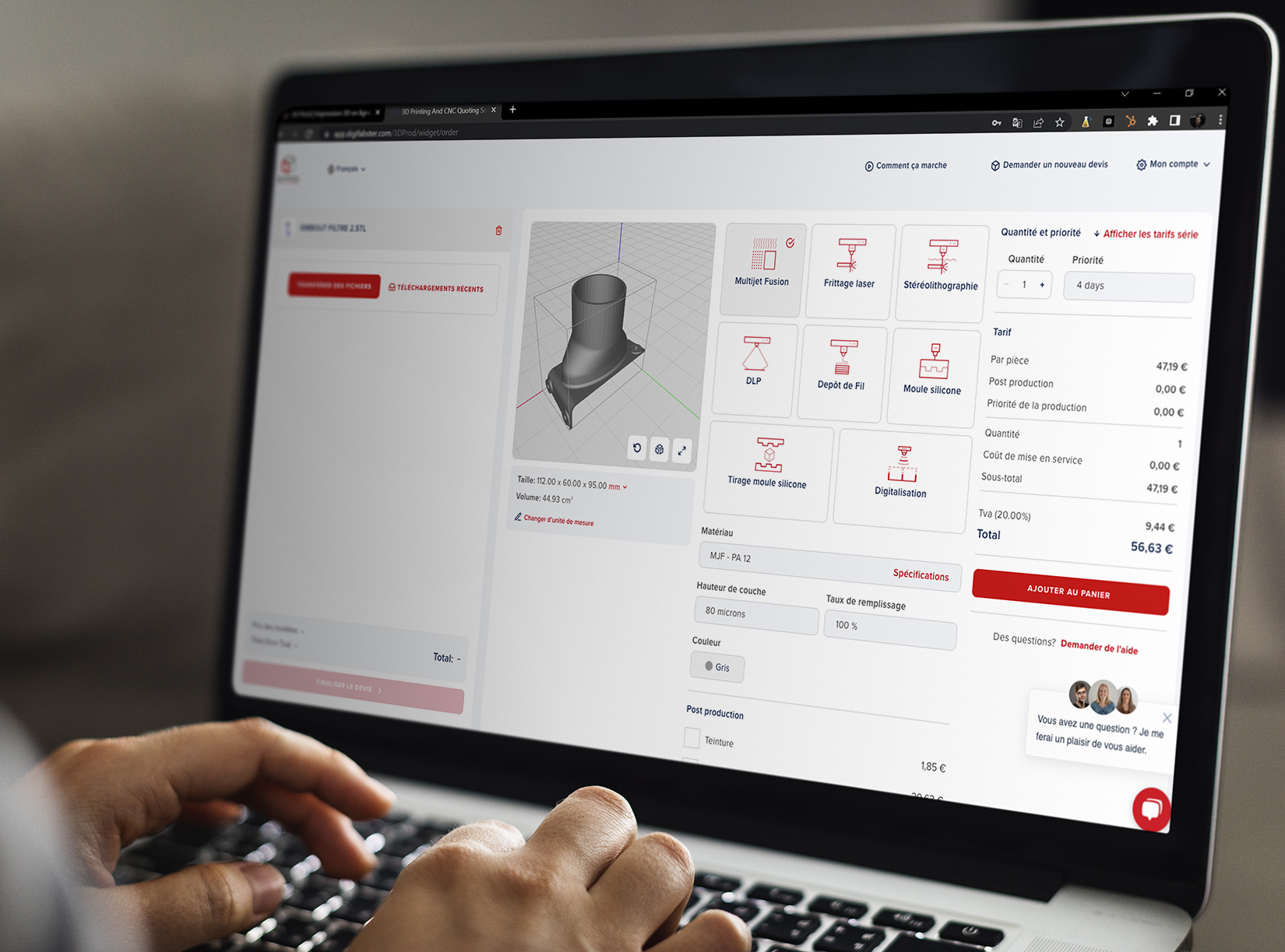

Your quote in minutes

Choose the technology, the material, the finish and get your quote instantly via our online platform.

1. Import your CAD file

Upload your 3D file (.stl, .obj, .wrl, .step (.stp), .iges (.igs), .3mf, .dxf or .zip (with models and textures) file not exceeding 100 Mb

2. Choose 3D technology and materials

Choose the ideal material from our vacuum casting resins and finishes and order online.

Our experts are at your disposal for all your 3D projects

Vacuum casting FAQs

Contact us today to discuss your project!

Our team will get back to you to make your project a reality!